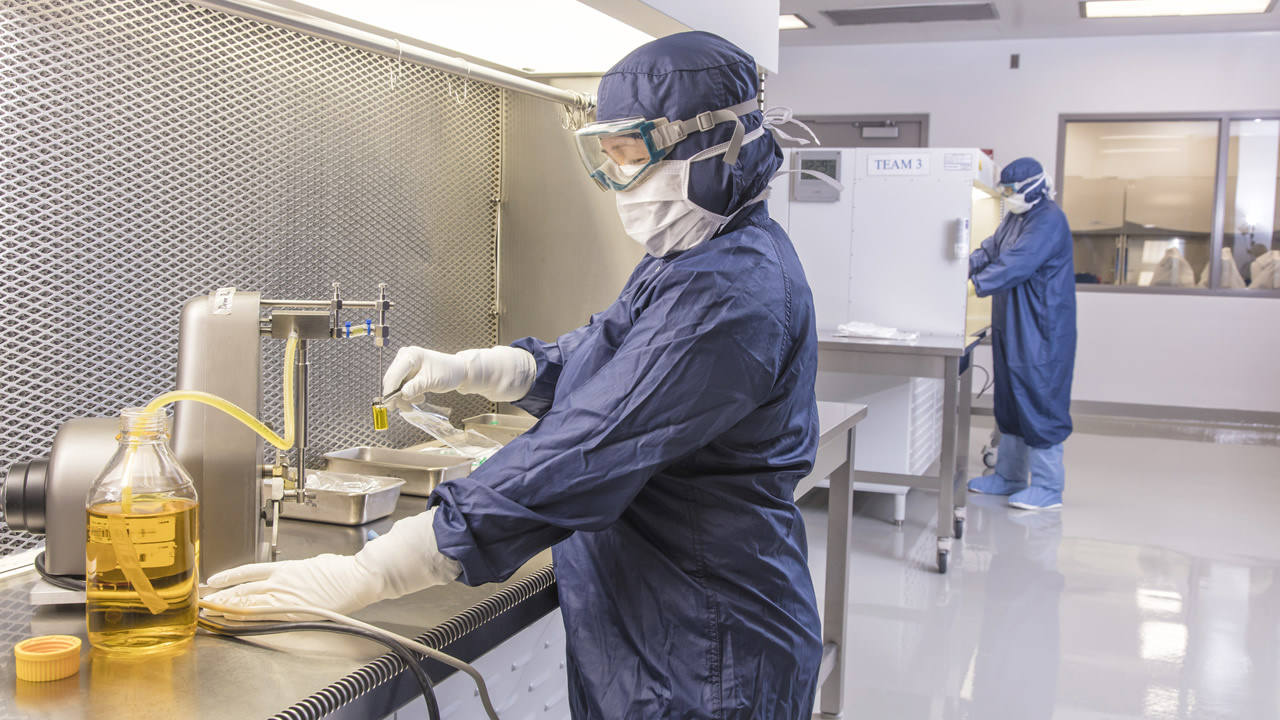

Are you new to the pharmaceutical or life science sectors? Need to brush up your skills? Learn and practice the basics of aseptic operations in a simulated CGMP environment.

CGMP exists to protect the health and safety of patients or consumers.

Aseptic Processing Level I provides the foundational knowledge and practical hands-on training you need to be successful in your career.

Aseptic technique is vital for maintaining product integrity and customer safety. Currently, this class is only offered at our BioNetwork Capstone Center in Raleigh, NC.

This course equips professionals whose responsibilities depend on aseptic technique:

- Manufacturing Technicians

- Team Leaders and Supervisors

- Quality Control Personnel

- Quality Assurance Personnel

- Maintenance / Engineers – Aseptic Emphasis

- Future Cosmetic Industry Employees

This course meets six hours per day for four days and is aligned with regulatory guidelines. It covers:

- What Is Aseptic Processing and Why Is It Important?

- Current Good Manufacturing Practices (CGMP)

- Good Documentation Practices

- Microbiology Basics

- Environmental Monitoring

- Facility Cleaning and Disinfection

- Aseptic Gowning

- Component Preparation

- Solution Preparation and Filtration

- Sterilization Methods

- Explain the role aseptic processing plays in pharmaceutical manufacturing.

- Discuss microbiology in the context of parenteral drug manufacturing.

- Describe cleanroom operations in relation to manufacturing parenteral products.

- Experience aseptic gowning, practice cleaning in a cleanroom, and use environmental monitoring techniques.

- Apply CGMP knowledge to cleanroom activities.

- Perform aseptic filtration and filter integrity tests.

Delivered in-person in a classroom or lab setting.

Are you new to the pharmaceutical or life science sectors? Need to brush up your skills? Learn and practice the basics of aseptic operations in a simulated CGMP environment.

CGMP exists to protect the health and safety of patients or consumers.

Aseptic Processing Level I provides the foundational knowledge and practical hands-on training you need to be successful in your career.

Aseptic technique is vital for maintaining product integrity and customer safety. Currently, this class is only offered at our BioNetwork Capstone Center in Raleigh, NC.

This course equips professionals whose responsibilities depend on aseptic technique:

- Manufacturing Technicians

- Team Leaders and Supervisors

- Quality Control Personnel

- Quality Assurance Personnel

- Maintenance / Engineers – Aseptic Emphasis

- Future Cosmetic Industry Employees

This course meets six hours per day for four days and is aligned with regulatory guidelines. It covers:

- What Is Aseptic Processing and Why Is It Important?

- Current Good Manufacturing Practices (CGMP)

- Good Documentation Practices

- Microbiology Basics

- Environmental Monitoring

- Facility Cleaning and Disinfection

- Aseptic Gowning

- Component Preparation

- Solution Preparation and Filtration

- Sterilization Methods

- Explain the role aseptic processing plays in pharmaceutical manufacturing.

- Discuss microbiology in the context of parenteral drug manufacturing.

- Describe cleanroom operations in relation to manufacturing parenteral products.

- Experience aseptic gowning, practice cleaning in a cleanroom, and use environmental monitoring techniques.

- Apply CGMP knowledge to cleanroom activities.

- Perform aseptic filtration and filter integrity tests.